A computer-driven automated drill, similar to those used to machine auto parts, could play a pivotal role in future surgical procedures. The new machine can make one type of complex cranial surgery 50 times faster than standard procedures, decreasing from two hours to two and a half minutes.

A computer-driven automated drill, similar to those used to machine auto parts, could play a pivotal role in future surgical procedures. The new machine can make one type of complex cranial surgery 50 times faster than standard procedures, decreasing from two hours to two and a half minutes.

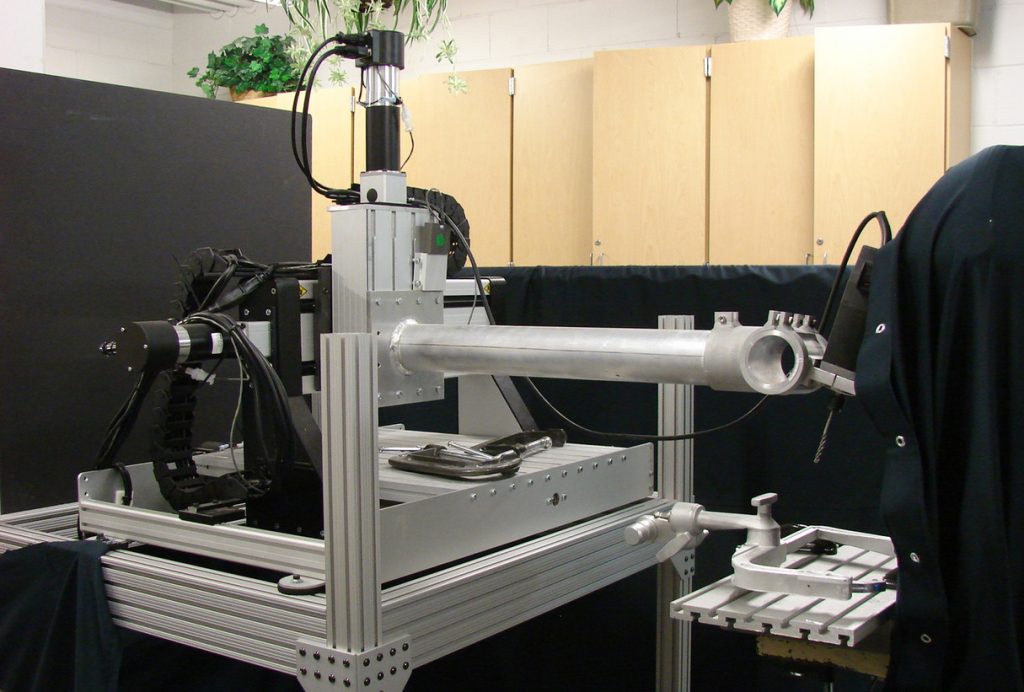

Researchers at the University of Utah developed the drill that produces fast, clean and safe cuts, reducing the time the wound is open and the patient is anesthetized, thereby decreasing the incidence of infection, human error, and surgical cost. The findings were reported online in the May 1 issue of Neurosurgical Focus.

To perform complex surgeries, especially cranial surgeries, surgeons typically use hand drills to make intricate openings, adding hours to a procedure. “It was like doing archaeology,” said William Couldwell, a neurosurgeon at University of Utah Health. “We had to slowly take away the bone to avoid sensitive structures.”

He saw a need for a device that could alleviate this burden and make the process more efficient. “We knew the technology was already available in the machine world, but no one ever applied it to medical applications.” Couldwell led an interdisciplinary team at the U to bring the drill into reality.

“My expertise is dealing with the removal of metal quickly, so a neurosurgical drill was a new concept for me,” explained A. K. Balaji, associate professor in mechanical engineering at the U. “I was interested in developing a low-cost drill that could do a lot of the grunt work to reduce surgeon fatigue.”

The team developed the drill from scratch to meet the needs of the neurosurgical unit, as well as developed software that sets a safe cutting path.

First, the patient is imaged using a CT scan to gather bone data and identify the exact location of sensitive structures, such as nerves and major veins and arteries that must be avoided. Surgeons use this information to program the cutting path of the drill. “The software lets the surgeon choose the optimum path from point A to point B, like Google Maps,” said Balaji. In addition, the surgeon can program safety barriers along the cutting path within 1 mm of sensitive structures. “Think of the barriers like a construction zone,” said Balaji. “You slow down to navigate it safety.”

The drill does the heavy lifting by removing most of the bone, similar to a mill, accurately and rapidly. “It’s like Monster Garage, except instead of machining a part, we are machining the skull,” said Couldwell.

Couldwell applied the new drill to the translabyrinthine opening, a particularly complex jigsaw-like shape that circumnavigates the ear. “The access is through the temporal bone which is a hard bone with strange angles,” said Balaji. According to Couldwell, this particular cut requires a lot of experience and skill to perform it safely. “We thought this procedure would be a perfect proof of principle to show the accuracy of this technology,” he said.

The translabyrinthine surgery is performed thousands of times a year to expose slow-growing, benign tumors that form around the auditory nerves. This cut is not only difficult, the cutting path also must avoid several sensitive features, including facial nerves and the venous sinus, a large vein that drains blood from the brain. Risks of this surgery include loss of facial movement.

The device also has an automatic emergency shut-off switch. During surgery, the facial nerve is monitored for any signs of irritation. “If the drill gets too close to the facial nerve and irritation is monitored, the drill automatically turns off,” said Couldwell.

The new drill could reduce the duration of this complex procedure from two hours for hand-drilling by an experienced surgeon to two and a half minutes. The shorter surgery is expected to lower the chance of infection and improve post-operative recovery. It also has potential to substantially reduce the cost of surgery, because it shaves hours from operating room time.

The research team has demonstrated the safety and speed of the drill by performing this complex cut, but Couldwell stresses that it can be applied to many other surgical procedures. “This drill can be used for a variety of surgeries, like machining the perfect receptacle opening in the bone for a hip implant,” he said.

The varied application of the drill emphasizes another factor that drew Balaji to the project. “I was motivated by the fact that this technology could democratize health care by leveling the playing field so more people can receive quality care,” he said.

Couldwell and his team are examining opportunities to commercialize the drill to ensure that it is more widely available for other surgical procedures.