Last year, the Utah System of Higher Education (USHE) established the Utah Workforce for Biotherapeutics (UWB) Deep Tech Initiative, supporting educational programs that give Chemical Engineering students at the U training in a cutting-edge new class of medicines.

Also known as biologics, these medications are the product of living cells; mass-producing them for patients therefore requires techniques at the intersection of multiple high-tech disciplines.

Denali Therapeutics, a South San Francisco-based biotech company, has just opened Utah’s first industrial-scale biotherapeutics manufacturing facility. In addition to producing biologics for clinical trial testing of potential new treatments for neurological disorders, the 60,000 square foot plant will advance education and training in this growing field.

Denali is one of the local businesses partnering with Chemical Engineering’s DeepTech program, supporting hands-on learning that the University of Utah students receive in biomanufacturing of biologics, and providing insights from industry professionals. Denali’s co-founder and CEO, Ryan Watts, is a University of Utah alumnus; Leah Frautschy, Denali’s VP of Clinical Manufacturing, sits on the program’s Industrial Advisory Board.

“We are excited to partner with the University of Utah in their efforts to build a program preparing students for future careers in the biotech industry,” says Frautschy. “The university’s program will support the continued growth of the life sciences ecosystem here in Utah while advancing biomanufacturing capabilities in the U.S.”

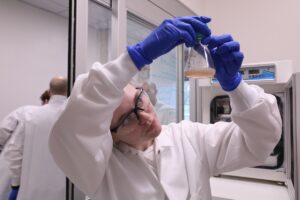

The processes involved in biomanufacturing require highly specialized source materials and stringently sterile handling. Simply having the opportunity to practice the basic skills involved in these processes — without risking millions of dollars worth of product — is a critical aspect of workforce development.

“As luck would have it, Denali’s workflow, down to the type of cells they use, is remarkably similar to what we implemented in our course focused on biomanufacturing of monoclonal antibodies,” says Misha Skliar, professor in the John and Marcia Price College of Engineering’s Department of Chemical Engineering and principal investigator of the UWB Initiative.

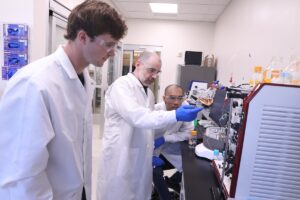

Skliar, co-principal investigator Tom Zangle, as well as students of the UWB program, spoke with Utah’s TechBuzz News at the ribbon-cutting of the new Denali facility:

“Fundamentally, we’re teaching students and enabling research in this new type of therapeutics, for both treating disease and maintaining health. We feel that there is a market for students to be involved because we think this initiative is going to grow quite substantially. The students in this program will get to do things researchers are doing here at Denali—on a smaller scale—but using similar equipment and similar processes. This is an exciting part of their education.”

Maxim Balitskiy, a chemical engineering major at the University of Utah and a member of the current team of deep tech students collaborating with Denali, noted the importance of companies like Denali in inspiring the next generation of biotech professionals. Balitskiy started his career in semiconductor manufacturing and more recently shifted his focus to biomanufacturing.

“I believe that classes like this, where students get hands-on and industry conducive experience are not only good for students like us, but also grant benefits to the companies that students eventually go into,” said Balitskiy. “I’m really excited to see what Denali has going on, and I’m thankful for the opportunity to see their state-of-the-art facility open up!”